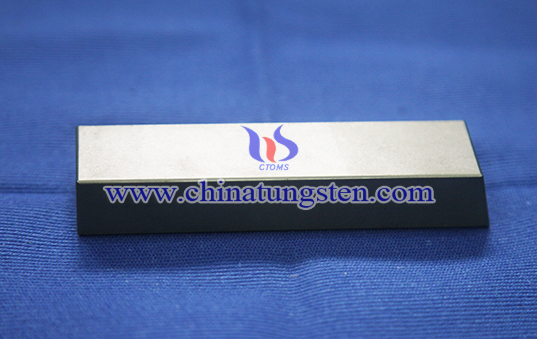

Rivet block is a work tool received behind work surfaces to provide a backing member in applying impact fasteners and including intermitted toolhead and handle parts with a low-recoil impact-absorbing spacer provided there between to take shock loads in compression and shear. The rivet block forms bucktails on rivets and comes in many different shapes and sizes. The particular shape to be used depends upon the location and accessibility of the rivet to be driven. Its size and weight depend on the size and alloy of the rivet to be driven. Under certain circumstances, and for specific rivet installations, specially designed rivet blocks are manufactured locally.

Tungsten alloys that are liquid-phase sintered are traditionally called tungsten heavy alloys (WHAs). The most common WHAs have Ni-Fe or Ni-Cu matrices, although other transition metals such as Co, Mo and Mn are sometimes added or substituted to improve properties or lower sintering temperatures. According to the American Standard ASTM B777-2007, the high-density tungsten alloys are divided into four grades, where in the tungsten content is 90%, 92.5%, 95% and 97%, respectively, and the rest are nickel, iron, Copper and so on. Considering the excellent characteristics of high density, high hardness, good ductility, electrical conductivity and thermal conductivity, tungsten alloys are the best materials to produce rivet block.

If you have any interest in rivet block, please feel free to contact us by email: sales@chinatungsten.com sales@xiamentungsten.com or by telephone:0086 592 5129696.