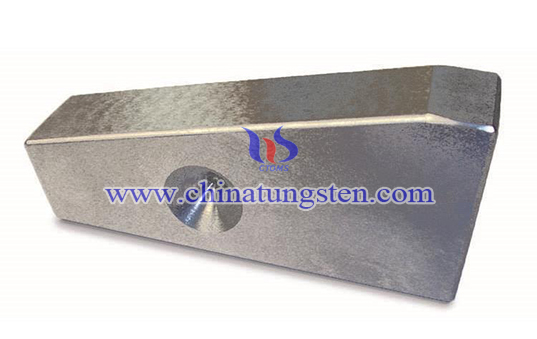

Tungsten bucking kit is not a one size fit all affairs. Different areas require various sizes and shapes in the process of aircraft maintenance. There are quite a few options when it comes to choosing to purchase a tungsten bucking kit. Because of the chemical properties of the metal and various practical reasons during manufacture, bucking kit made of tungsten are not 100% pure, instead, heavy metal alloys made of tungsten and nickel are used. These heavy metal alloys allow for enhanced machinability and permit manufacturers of bars to offer products with higher rigidity, lower vibration, higher damping, and reduce thermal expansion properties.

How do you take the edge off trying to avoid scratches and material fatigue? By taking the edge off. Rounding the sides on our bucking kits enables us to protect the materials' surfaces, prevent scratching, and ease fatigue on certain areas of the aircraft - avoiding skin damage to aircraft. Moreover, the operators will not get hurt during the process and can be easier to hold the kit to increase work efficiency.

If you have any interest in tungsten bucking kit, please feel free to contact us by email: sales@chinatungsten.com sales@xiamentungsten.com or by telephone:0086 592 5129696.