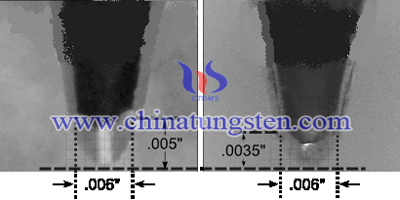

Typically, a new steel needle is required for every record played on an old acoustic phonograph. This is because the record contains abrasive material. In the first few silent tracks this abrasion hones the steel needle to a profile that tracks the grooves properly. The needle continues to wear as it plays the record, so that by the end its diameter has increased to the point where the sharp edges may damage the grooves on subsequent plays.Tungsten wire phonograph stylus have high hardness to decrease the wear.

(a),Generic phonograph stylus (b),Tungsten wire phonograph stylus

The tungsten wire phonograph stylus are smooth, free of twists, bends, kinks, curls, and as free of dents, swaging marks, scratches, die marks, laps, seams, splits, slivers, inclusions, bumps, pits, grooves, cracks, and other physical defects Unless black finish is specified, all types of wire have a clean finish, free of graphite, grease, oil, and lubricants. Wire for hooks, supports, springs, anchors, and mesh have a bright smooth surface free of cracks holes, or craters. The requirements for straightness, and coiling and spooling are detailed as well. We can provide all kinds of tungsten phonograph stylus according to your requirements.

Properties of bare tungsten wire:

Purity99.95% W

Melting point3410 °C

Density19.17 g/cm3

Specific electrical0.055 Ohm x mm2/m

resistance at 20 °C

Modulus of elasticity410 kN/mm2at 20 °C

If you have interest, just feel free to contact our sales team sales@chinatungsten.com.