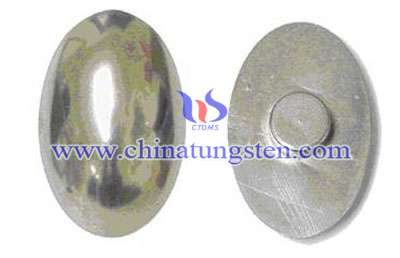

One main difference between the three metals is their density. The more dense the metal, the more it will weight. The picture to the right shows the three metals and the amount need of each for the same weight. As you can see, it takes a lot less tungsten then steel for the same weight.

| Advantages | Disadvantages | |

| Lead | Soft - easy to bend and cut. Low cost Medium density |

Keep it away from children Only available in one form - 1/4" cylinders. |

| Steel | Low cost Can be cut | Low density Can rust |

| Tungsten | High density Ideal for concentrating weight in limited area | High cost Very hard - Cannot be cut or shaped |

Tungsten alloy canopy weight can be easily used for pinewood derby car weighting if the weight of the car body, wheels, and axles is less than 1.5 ounces. Drill a 1/2 inch diameter hole into the top of the car body (generally the hole is drilled all the way through the car). Apply epoxy in the hole, and spread just a little epoxy on the top of the car as well. Mount the product and allow it to dry.

Since tungsten alloy weight is very hard, do not plan to drill out any extra weight. Instead, use an alternate method to make fine adjustments such as adding/removing tungsten beads, lead, or other items.