Tungsten copper alloy application may be used in the most severe applications associated with power generation and transmission, where where the fast working switch may be totally immersed in oil. In these cases, there is no advantage in using the tarnish resistant silver-based materials, as oxidation is prevented by the exclusion of air. Tungsten copper application is widely used in these cases, the selection of the grade used being dependent on the relative importance of conductivity and arc resistance.

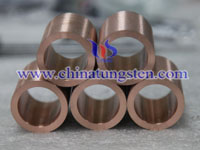

Tungsten copper application is also widely used in such industries as engine, electrical power, electron, metallurgy, spaceflight and aviation. Using CIP formation, sintered tungsten skeleton and copper infiltrating (silver) technology, large size and special shape products of copper tungsten alloy composites with 6-90 percent of copper are produced, such as electric contacts, electrode, refractory parts, heat sinks and parts of rocket, We can also produce copper tungsten alloy sheets, tubing, plate and other small products by mould pressing, extrusion pressing and MIM with different tungsten copper alloy application..

Tungsten copper alloy application is widely used where the combination of high heat resistance, high electrical and/or thermal conductivity, and low thermal expansion are needed. Some of the applications are in electric resistance welding, as electrical contacts, and as heat sinks. As contact material, the alloy is resistant to erosion by electric arc. WCu alloys are also used in electrodes for electrical discharge machining and electrochemical machining.

;

Tungsten copper application is also widely used for EDM and ECM, which are far superior with fine surface finishes. Deep narrow slots or ribs and small precise holes are required. Tungsten copper application are preferred when matching extremely detailed sections. In the ECM process, copper tungsten alloy withstands erosive effects of short circuit malfunctions far better than other materials.

Tungsten copper application in electrical contact materials mainly apply to vacuum interrupter of vacuum load breaker switches, vacuum contactor, among them the product of WCu10 occupy national market quota 70%. Tungsten copper application material is produced by powder metallurgy method have high density, high heat conduction, high tensile strength, high rigidity, low resistance, and low coefficient of expansion, fine electric arc resistance, fine fusion welding resistance, and good galvanic corrosion resistance. They are widely used as electrical contact materials and electrode materials.

If you have any interest in our tungsten copper application, please feel free to contact us by email: sales@chinatungsten.com sales@xiamentungsten.com or by telephone: 0086 592 5129696. We are at your service at all times.