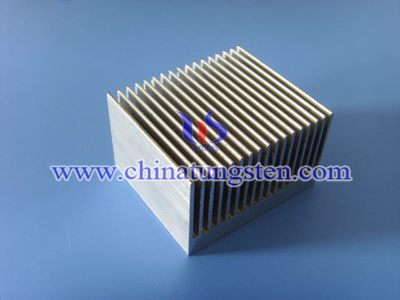

Tungsten copper ultra thin sheet, as heat sink uses its extended surfaces to increase the surface area in contact with the cooling fluid, the air The term is not meant literally, as a heat sink does not have a "magical ability to absorb heat like a sponge and send it off to a parallel universe". Heat transfer theory helps explain practical aspects of how heat sinks work, and can help to clear up common misconceptions and design mistakes. Approach air velocity, choice of material, fin (or other protrusion) design and surface treatment are some of the design factors which influence the thermal resistance, i.e. thermal performance, of a heat sink. One engineering application of heat sinks is in the thermal management of electronics, often computer CPU or graphics processors. For these, heat sink attachment methods and thermal interface materials also influence the eventual junction or die temperature of the processor(s). Theoretical, experimental and numerical methods can be used to determine a heat sink's thermal performance.

Tungsten copper ultra thin sheet, as heat sink uses its extended surfaces to increase the surface area in contact with the cooling fluid, the air The term is not meant literally, as a heat sink does not have a "magical ability to absorb heat like a sponge and send it off to a parallel universe". Heat transfer theory helps explain practical aspects of how heat sinks work, and can help to clear up common misconceptions and design mistakes. Approach air velocity, choice of material, fin (or other protrusion) design and surface treatment are some of the design factors which influence the thermal resistance, i.e. thermal performance, of a heat sink. One engineering application of heat sinks is in the thermal management of electronics, often computer CPU or graphics processors. For these, heat sink attachment methods and thermal interface materials also influence the eventual junction or die temperature of the processor(s). Theoretical, experimental and numerical methods can be used to determine a heat sink's thermal performance.

Tungsten copper ultra thin sheet high performance composites are fabricated from carefully controlled porous tungsten that is infiltrated with molten copper. This results in a WCu composite that has high conductivity and a matched low thermal expansion for heat sinks.

Our tungsten copper ultra thin sheet composite is used extensively in thermal mounting plates, chip carriers, flanges, and frames for high-powered electronic devices. With the thermal advantages of copper with the very low expansion characteristics of tungsten, tungsten copper has properties similar to those of silicone carbide, aluminum oxide, and beryllium oxide. The thermal conductivity and low expansion also make tungsten copper alloy an excellent choice even for extremely dense circuits.

The CuW75 tungsten copper is used extensively in thermal mounting plates, chip carriers, flanges, and frames for high-power electronic devices. As a tungsten copper material, it is a composite, so both the thermal advantages of copper and the very low expansion characteristics of tungsten can be utilized.

The combination of tungsten & copper materials results in thermal expansion characteristics similar to those of silicone carbide, aluminum oxide, and beryllium oxide, used as chips and substrates. Because of tungsten copper's thermal conductivity and expansion characteristics, Tungsten copper alloy works well in densely packed circuits.

Advantages of tungsten copper ultra thin sheet:

Good electrical conductivity

Thermal conductivity

Low thermal diffusion

Applications of tungsten copperultra thin sheet:

LED lighting tungsten copper heat sink

Laser field of tungsten copper heat sink

Tungsten copper alloy conductive switch of the electronic field

More Info>>

1.Tungsten Copper

2.Tungsten Copper Sheet

If you want to know more details about tungsten copper ultra thin sheet, please feel free to contact us by email: sales@chinatungsten.com or call: 0086 592 5129696.