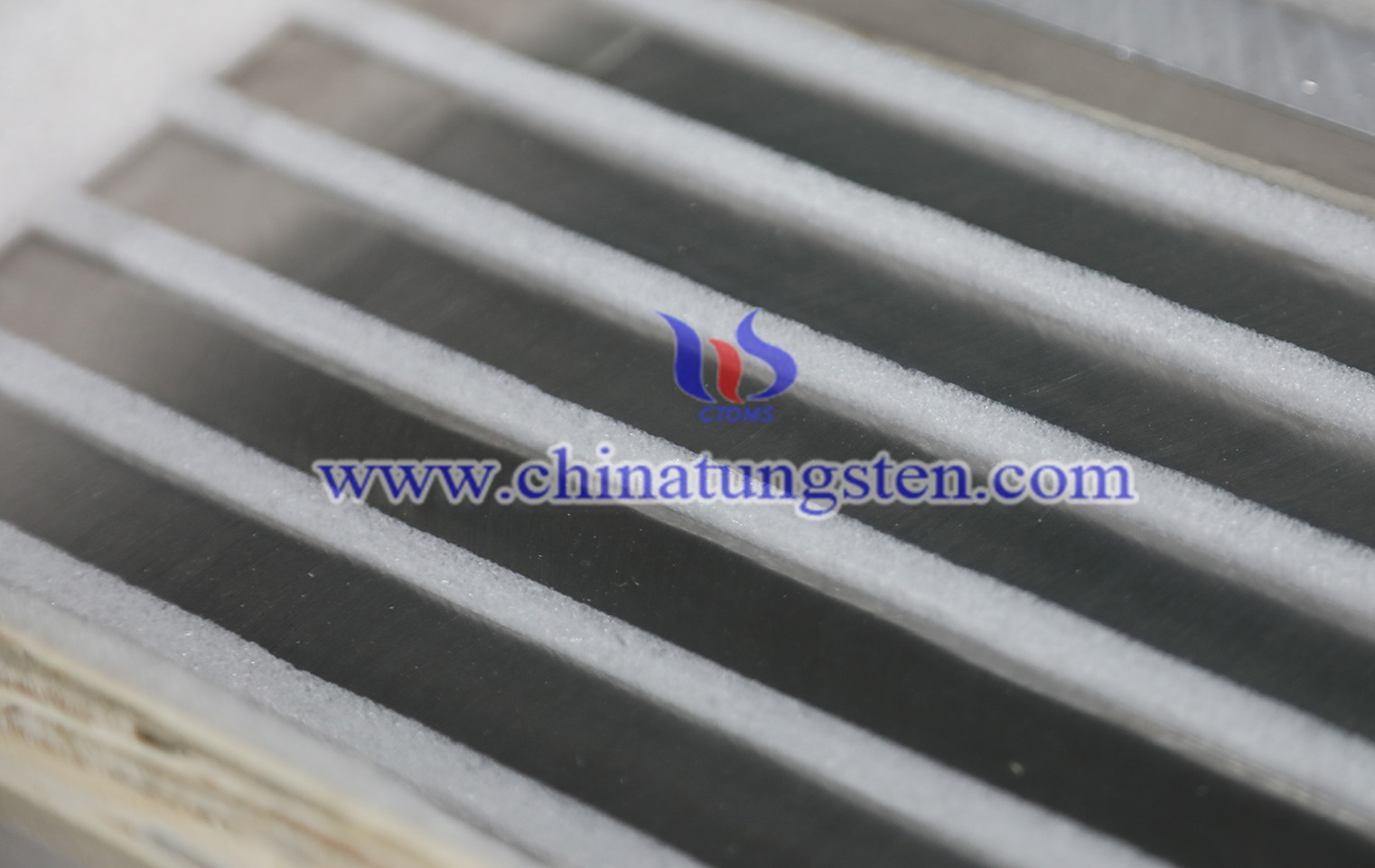

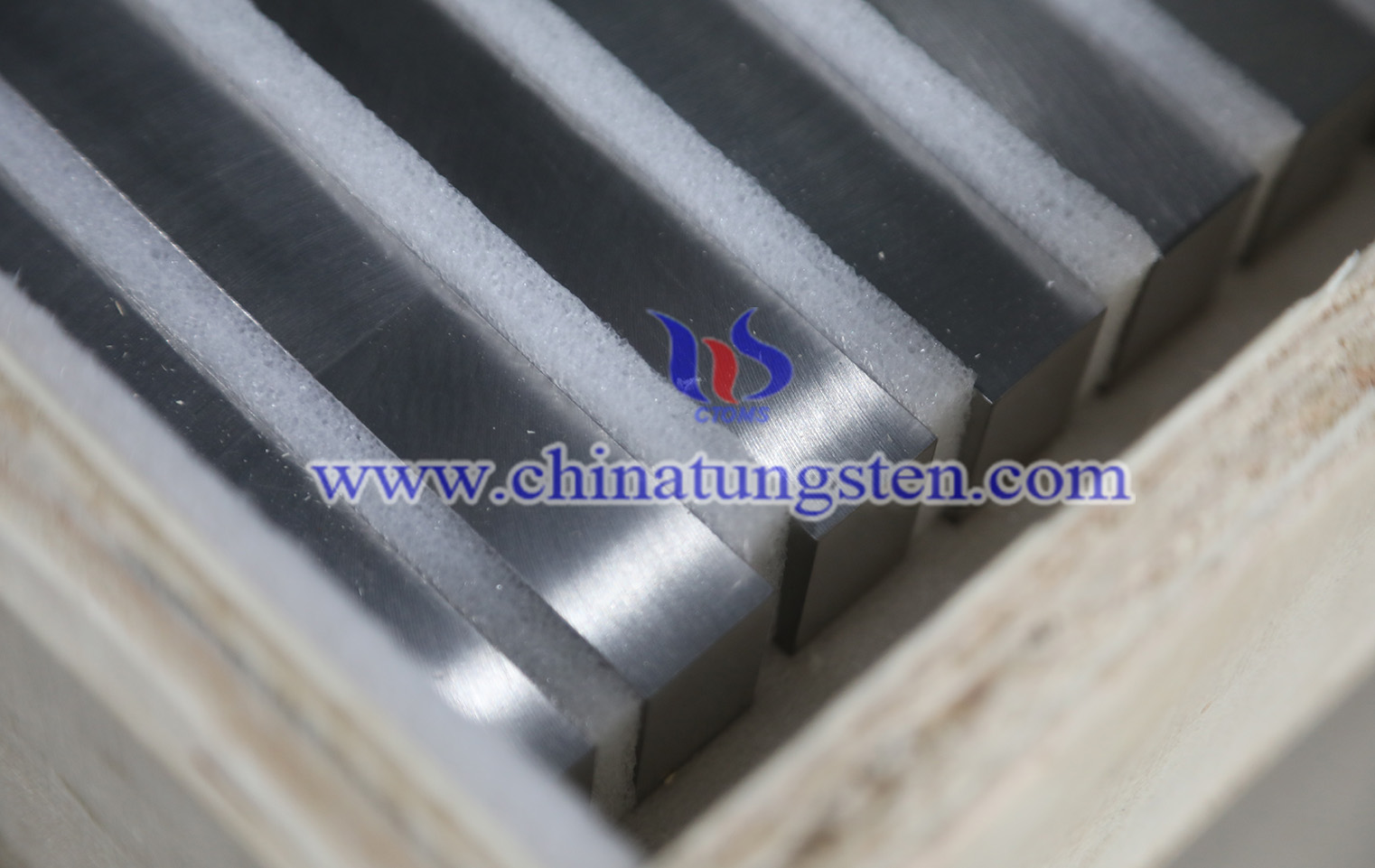

90WMoNiFe tungsten alloy bar is a high-density, tungsten-based alloy composed of tungsten (W), molybdenum (Mo), nickel (Ni), and iron (Fe). It is commonly used in industrial, military, and high-performance engineering fields.

Composition and Structure

1. Main Components:

Tungsten (W): Approximately 90%, providing high density and high-temperature strength.

Molybdenum (Mo): Enhances high-temperature performance and corrosion resistance.

Nickel (Ni) and Iron (Fe): Act as binding phases, improving the alloy’s toughness and machinability.

2. Microstructure:

Primarily tungsten-based particles, with a matrix of nickel, iron, and molybdenum forming a uniformly distributed metal-based composite.

Performance Characteristics

1. High Density: With a density of approximately 17.1 g/cm³, it is suitable for applications requiring high specific gravity.

2. High Strength and Toughness: Capable of withstanding heavy loads while offering excellent impact resistance.

3. Superior High-Temperature Resistance: Retains strength in high-temperature environments.

4. Good Machinability: Easier to machine and form compared to pure tungsten.

5. Corrosion Resistance: Offers strong resistance to certain chemicals and environmental conditions.

Main Applications

1. Military Sector:

Manufacturing armor-piercing shells, kinetic energy penetrators, and other high-performance ammunition.

2. Aerospace:

Used for aircraft counterweights, vibration-damping components, and radiation shielding parts.

3. Nuclear Industry:

Serves as radiation shielding material and critical components.

4. High-Performance Machinery:

Produces molds, tools, and wear-resistant parts.

5. Medical Industry:

Used in shielding components for CT scanners and X-ray machines.

Processing and Production

The 90WMoNiFe alloy bar is typically produced through powder metallurgy:

1. Mixing: Tungsten powder is uniformly mixed with molybdenum, nickel, and iron powders.

2. Pressing and Forming: The powder mixture is compressed into shape using a mold under high pressure.

3. Sintering: The pressed form is sintered at high temperatures to create a dense alloy material.

4. Post-Processing: Depending on the application, further machining such as turning, milling, or grinding is carried out.

Chinatungsten specializes in manufacturing of tungsten alloy products. Any enquiry will be warmly welcomed by email to sales@chinatungsten.com or telephone to 0086 592 5129696.