Properties of Tungsten-Molybdenum-Nickel-Iron Alloy

1. Physical Properties

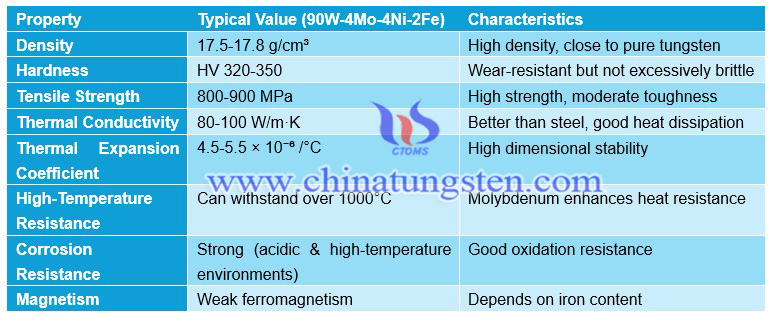

• Density:

• Range: 17.0-18.5 g/cm³ (varies with tungsten content).

• Examples:

o 90W-4Mo-4Ni-2Fe: ~17.5-17.8 g/cm³

o 95W-1Mo-3Ni-1Fe: ~18.5 g/cm³

• Characteristics:

o Close to pure tungsten (19.25 g/cm³)

o Significantly higher than steel (7.8 g/cm³) or lead (11.34 g/cm³)

o Suitable for high-density applications

• Melting Point:

• The tungsten matrix has a melting point of 3422°C, but the presence of nickel (1455°C) and iron (1538°C) lowers the overall melting point.

• Since this alloy is typically processed via liquid-phase sintering, its melting point is not directly applicable in practical use. However, it remains highly heat-resistant, capable of withstanding temperatures above 1000°C.

• Thermal Conductivity:

• Range: ~80-110 W/m·K

• Comparison:

o Higher than die steel (~20-30 W/m·K)

o Lower than pure tungsten (173 W/m·K)

• Feature:

o Excellent heat dissipation, making it suitable for high-temperature applications.

• Coefficient of Thermal Expansion:

• Range: ~4.5-5.5 × 10⁻⁶ /°C

• Comparison:

o Much lower than steel (11-13 × 10⁻⁶ /°C) or aluminum (23 × 10⁻⁶ /°C)

• Feature:

o High dimensional stability with minimal thermal deformation.

2. Mechanical Properties

• Hardness:

• Range: HV 300-450 (varies with tungsten content and heat treatment).

• Examples:

o 90W type: HV 320-350

o 95W type: Up to HV 400

• Characteristics:

o High hardness but lower than pure tungsten (HV 450-600)

o Strong wear resistance

• Tensile Strength:

• Range: 700-1000 MPa

• Example: 90W-4Mo-4Ni-2Fe: ~800-900 MPa

• Feature:

o High strength

o Nickel and iron enhance toughness, making it superior to brittle pure tungsten.

• Ductility:

• Elongation: 5%-25% (increases with higher nickel content).

• Feature:

o Significant improvement over pure tungsten, which has almost no ductility.

o Can withstand a certain degree of deformation without cracking.

• Compressive Strength:

• Range: 2000-2500 MPa

• Feature:

o Far exceeds ordinary steel

o Suitable for high-load or high-pressure environments

3. Chemical Properties

• Corrosion Resistance:• Stability:

• Stable under normal atmospheric conditions, resistant to decomposition and oxidation.

• Maintains structural integrity even at high temperatures (>600°C).

4. Other Properties

• Magnetism:

• The presence of iron (Fe) introduces weak ferromagnetism.

• Example: 90W-4Mo-4Ni-2Fe exhibits weak magnetism but is unsuitable for non-magnetic environments (e.g., MRI equipment).

• Compared to tungsten-nickel-copper alloys (which are non-magnetic), this alloy has distinct differences.

• Acoustic Properties:

• High density and hardness provide strong sound wave damping, making it suitable for vibration-damping applications.

• Machinability:

• Can be processed via turning, milling, and drilling.

• Superior to pure tungsten, which is hard and brittle.

• Nickel and iron act as binders, improving machinability.

Factors Affecting Properties

1. Tungsten Content:

• Higher tungsten (e.g., 95W): Increases density and hardness but reduces ductility.

• Lower tungsten (e.g., 90W): Improves machinability and toughness.

2. Molybdenum Content:

• Higher molybdenum (4%-10%): Enhances high-temperature strength and wear resistance but may slightly reduce density.

3. Nickel-Iron Ratio:

• High nickel (e.g., 5Ni-1Fe): Improves ductility.

• High iron (e.g., 2Ni-4Fe): Increases strength and magnetism.

4. Manufacturing Process:

• Liquid-phase sintering temperature (1300-1500°C) and cooling rate affect grain size and overall properties.

Summary of Properties

Chinatungsten specializes in manufacturing of tungsten alloy products. Any enquiry will be warmly welcomed by email to sales@chinatungsten.com or telephone to 0086 592 5129696.