Tungsten alloy uses with the continuous development of social civilization, the use of tungsten alloys more and more widely for example tungsten alloy uses in radiation shielding and tungsten alloy uses in military defense and tungsten alloy counterweight for sports and tungsten alloy uses in counterbalances etc.

Science medical developing so repaid, there are more and more radiation in our life, which has become a new trouble, such as X-ray radiation, gamma radiation (energetic electromagnetic radiation), radiation of alpha particles (helium atoms) beta particles (electrons) and cosmic radiation, etc.

Tungsten heavy alloy is a suitable raw material for radiation protection, as its combination of radiographic density (more than 60% denser than lead), mach inability, good corrosion resistance, high radiation absorption (superior to lead), simplified life cycle and high strength. Tungsten alloy uses can provide the same degree of protection as lead whilst significantly reducing the overall volume and thickness of shields and containers. Besides, compared with lead or depleted uranium in the past, tungsten heavy alloy radiation shielding is more acceptable in this case, for they are non-toxic.

|

|

|

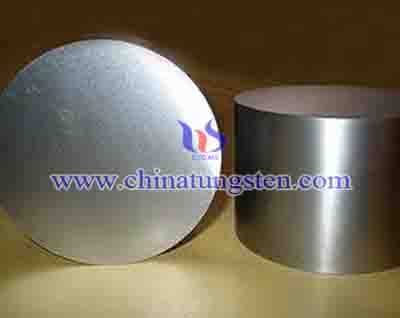

Tungsten Alloy Uses-1 |

Tungsten Alloy Uses-2 |

Tungsten Alloy Uses-3 |

Tungsten alloy uses in radiation protection is subject to NRC, EPA, or special OSHA regulations, so it has been widely used, such as nuclear medical, collimator, isotope container, source holder, cancer treatment, etc.

Tungsten alloy radiation shielding is a flexible heat-resistant shielding made of tungsten and iron metal powder immersed in a silicone polymer. Lead blankets have been the backbone of shielding applications for years but, in comparison, is a less effective and efficient shielding choice. Due to the ability to place the maximum amount of weight between the source and the worker, the new generation tungsten shielding has proven to be up to twice as effective as lead in lowering exposure rates.

Probably the most well known application for tungsten alloys is the aerospace industry, where weights and counterweights are often required to be housed in restricted areas. With significant reductions in size possible, this in turn, leads to greater control of weight distribution. These components can increase the sensitivity of control mechanisms and keep the forces required to operate flight controls within acceptable limits.

|

Tungsten alloy uses in aerospace applications include mass balances in satellites and helicopter rotor blades and in gyroscopic controls for missiles and avionics. In contrast to their vibration damping applications, these materials are also utilized, in the cockpit, to exaggerate the required vibrations in stall-warning shakers for control columns. Similarly, the advent of fly-by-wire controls has introduced small quantities of tungsten alloys into flight control joysticks, in order to increase stick inertia and therefore reintroduce some of the “feel” that is present in traditional controls, which use mechanical linkages to the elevators and ailerons. |

Please do not hesitate to contact us if you have any question about tungsten alloy uses. Our e-mail address is sales@chinatungsten.com sales@xiamentungsten.com. Or you can call us on 0086 592 5129595/5129696/5127878.