Tungsten Nickel Iron is a high-density alloy suitable for high-temperature environments and applications such as bearing assembly, ballast, casting, step soldering, and radiation shielding. Tungsten,nickel and iron alloys are available in numerous machined shapes such as bar, ingot, ribbon, wire, shot, sheet, and foil, in various dimensions. We can also produce materials to custom specifications by request. Ultra high purity and high purity forms also include metal powder, submicron powder and nanoscale, targets for thin film deposition, and pellets for chemical vapor deposition and physical vapor deposition applications. American Elements produces to many standard grades when applicable, including Mil Spec (military grade); , Reagent and Technical Grade; Food, Agricultural and Pharmaceutical Grade; Optical Grade, USP and EP/BP (European Pharmacopoeia/British Pharmacopoeia) and follows applicable ASTM testing standards. Typical and custom packaging is available, as is additional research, technical and safety (MSDS) data.

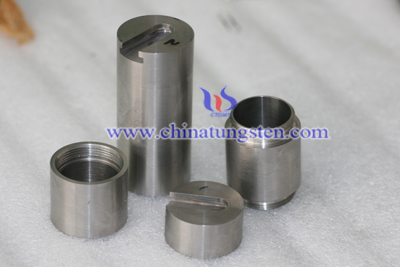

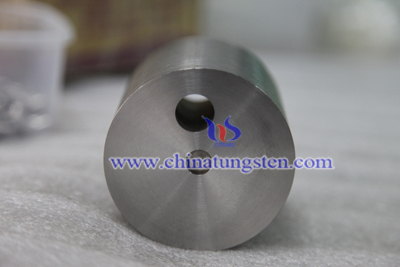

Tungsten, Nickel and Iron Alloys are ideal for high density applications or for use in radiation shielding. Heavy metal tungsten alloys are 90% to 97% pure tungsten in a matrix of nickel and and iron. The addition of these alloying elements improves both the ductility and machinability of these alloys over non-alloyed tungsten.

The most outstanding property of heavy metal alloys is the high density of 17-19 g/cm³. Comparable densities are only reached by gold or platinum metals, which are considerably more expensive. Other exotic materials like rhenium, uranium or tantalum achieve these densities, but are either too difficult or expensive to obtain, or they have unsatisfactory mechanical characteristics.