ng shaft nested inside the driven shaft. It engages more at higher speeds.

ng shaft nested inside the driven shaft. It engages more at higher speeds.

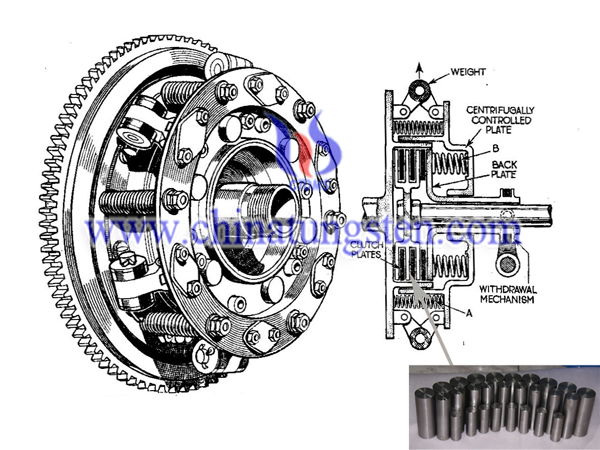

Tungsten alloy centrifugal clutch consists of two pieces, an inner clutch mechanism and an outer shell. The inner mechanism spins on the engine's output shaft while the outer shell and its attached sprocket remains still. As the engine's RPMs are increased, weights that are held in place by springs are thrown outward by the centrifugal force of the spinning mechanism, hence the moniker centrifugal clutch. As the weights reach their fully extended positions, they contact the outer shell and begin to drive it similar to releasing the clutch in an automobile. As the centrifugal clutch begins to spin faster, the vehicle begins to come up to speed. Compared with other materials, tungsten alloy has the advantage of high density. It can reduce size to limited space in vehicle and improve sensitivity of control mechanism.

Tungsten alloy centrifugal clutch is often used in mopeds, underbones, lawnmowers, go-karts, chainsaws, mini bikes, and some paramotors. More information, please visit: http://en.wikipedia.org/wiki/Centrifugal_clutch (Thanks Wikipedia show us the details about centrifugal clutch.)

Tungsten heavy alloy also has good machinability. It can be machined into rod, blocks, bricks and any other shapes. We can also produce tungsten alloy centrifugal clutch to meet your special requirements.

If you have any interest in tungsten alloy centrifugal clutch, please feel free to email us: sales@chinatungsten.com sales@xiamentungsten.com or call us by: 0086 592 512 9696, 0086 592 512 9595.