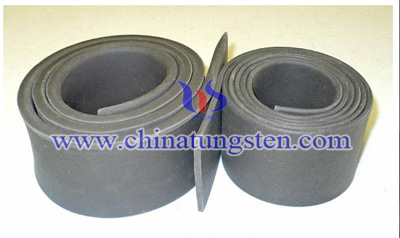

With the same density, tungsten blanket has the similar thickness than lead blankets. And highly flexible and can be molded or formed into any shape. It often competitively priced to lead alternatives. It will engineer and fabricate specialized profiles, slabs and ribbon, including lockable "High Rad" applications.

Here, the method described above has an effect of preventing direct reaction of Ti and WF.sub.6 when an adhesion layer is a laminated layer of Ti/TiN films and a tungsten shielding blanket is formed on the adhesion layer. A direct reaction of Ti and WF.sub.6 will form a solid substrate which will exhibit a volume expansion and become a cause of peeling-off of a layer.

When an adhesion layer for forming a tungsten shielding blanket is formed by sputtering, the substrate is often fixed on a mount using a holder or hooks. At portions under these hooks, a SiO.sub.2 film which is an inter-layer insulating layer is exposed because almost no film is formed under the hooks by sputtering. When a tungsten shielding blanket grows on the exposed SiO.sub.2, the tungsten shielding blanket is easily peeled off because of weak adhesion anti particles are produced.

To prevent a growth of tungsten blanket on the exposed SiO.sub.2 film, the exposed SiO.sub.2 film around the substrate is covered with a ring for preventing reaction gas from reaching the exposed film of SiO.sub.2.

In the prior art method of forming tungsten blanket described above, when a gas of SiH.sub.4 or SiH.sub.2 Cl.sub.2 is allowed to flow on a surface of a substrate for forming thereon a thin film of silicon, it is not supplied on the portion covered by a ring for preventing penetration of reaction gas. Thus, a layer of SiO.sub.2 is exposed on a periphery of the substrate.

In the next process of forming WSi film by providing a flow of WF.sub.6 gas, WF.sub.6 may penetrate into a portion where SiO.sub.2 film is exposed on a periphery of the substrate. In this case, tungsten blanket grows directly on the SiO.sub.2 film, and results in a production of particles.

If you have any interest in tungsten shielding blanket, please feel free to contact us by email: sales@chinatungsten.com sales@xiamentungsten.com or by telephone:86 592 5129696.