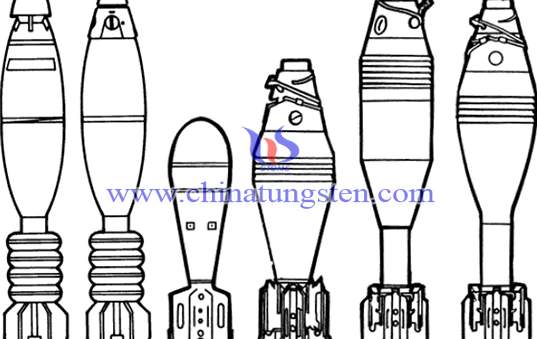

Tungsten alloy controlled fragment made of pre-processed tungsten alloy fragments is glued to the outer lining of the charge or the inner cavity of the warhead shell to maintain a certain shape. It is mainly used for high energy explosive. The commonly used controlled fragments are spherical, cube, rod, short column and arrow.

Controlled fragments of different shapes have different effects on the damage effect of fragments. The best match between the mass, shape and speed of the fragment can be achieved in the design ammunition, thus the prefabricated fragment has been widely used. For any given target, the optimum killing effect can be achieved by designing suitable prefabricated chip shapes and materials.

The grooves in the controlled fragment are produced by powder metallurgy injection molding technology. But the technology is easy to cause the ring-shaped blank to undergo adhesion and deformation due to liquid phase shrinkage in the subsequent high-temperature sintering, even with subsequent processing by bathing, grinding, etc., the width and depth of grooves are difficult to meet uniform. In order to overcome these difficulties, a processing device for producing ring-shaped or barrel-shaped grooves has been invented, thereby achieving high quality, high efficiency and mass production, satisfying the high quality of military.

If you have any interest in tungsten alloy controlled fragment, please feel free to contact us by email: sales@chinatungsten.com or by phone: 86 592 5129696.