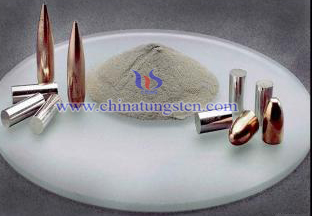

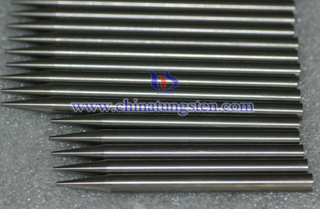

Besides, as a high density metal, tungsten is mixed with the binder such as nickel, iron, copper, cobalt, etc. to produce the components with controlled density and mechanical properties. Powder metal mixtures such as tungsten small caliber core is simply cold pressed to produce a high-density material with superior properties, e.g. high hardness, good ultimate tensile strength, excellent elongation, etc.

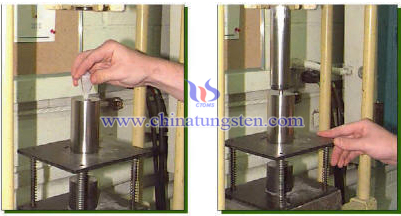

The combined processes of mechanical interlocking and "cold-welding" bond the metals together, and can be varied to control the properties of the non-lead core. Tungsten small caliber core can be pressed directly to shape, or cores can be produced that can be swaged into projectiles, with or without jacketing. So swaging is another important process for reaching a higher hardness at least 40HRC, meanwhile, ultimate tensile strength could be also increased to at least 1050Mpa. If the properties are needed higher, some of the processes would be adjusted.

High hardness 40HRC min. (Regular tungsten material only about 28HRC)

Excellent ultimate tensile strength 1050MPa min. (Regular tungsten material only about 900Mpa)

Non-toxic to the environment

Superior machinability

If you have any other questions about tungsten small caliber core, please feel free to contact us by email: sales@chinatungsten.com or call: 00 86 592 5129696.